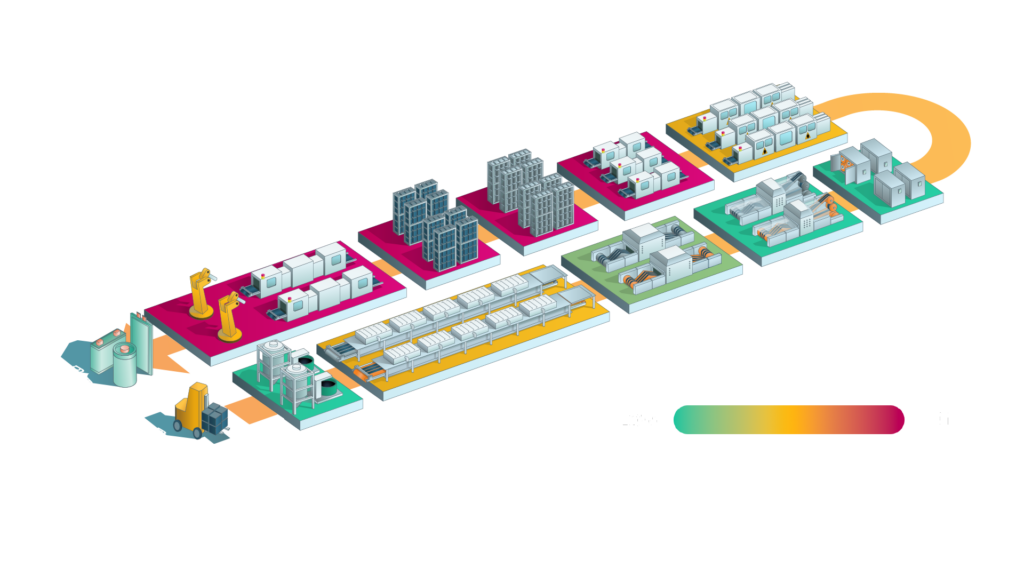

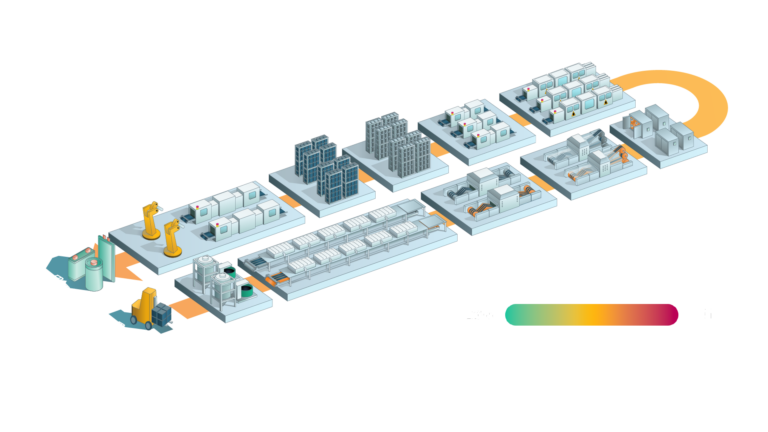

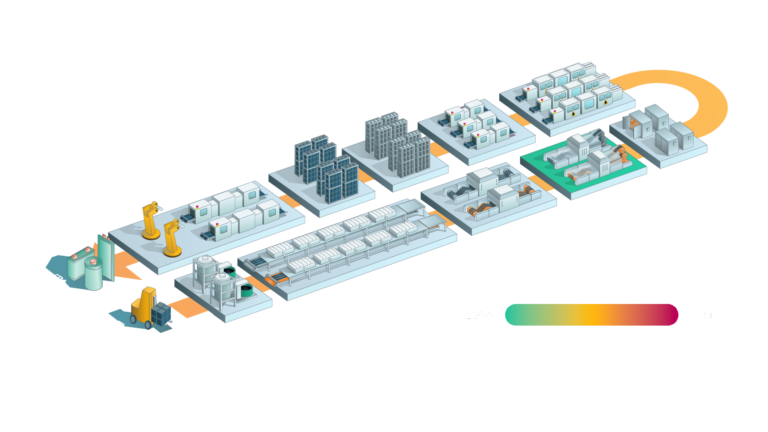

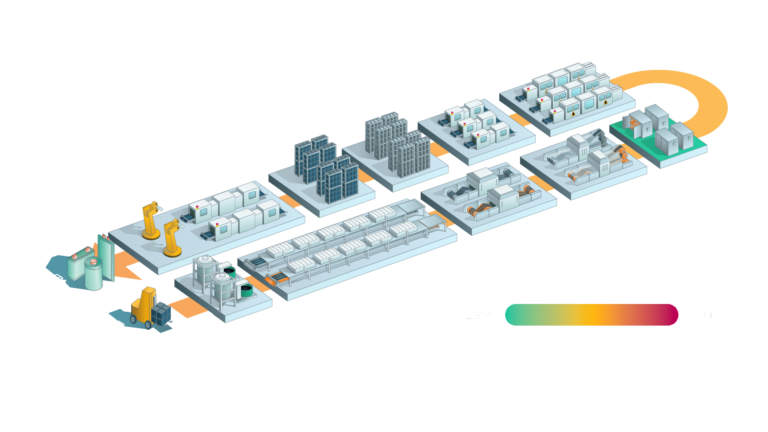

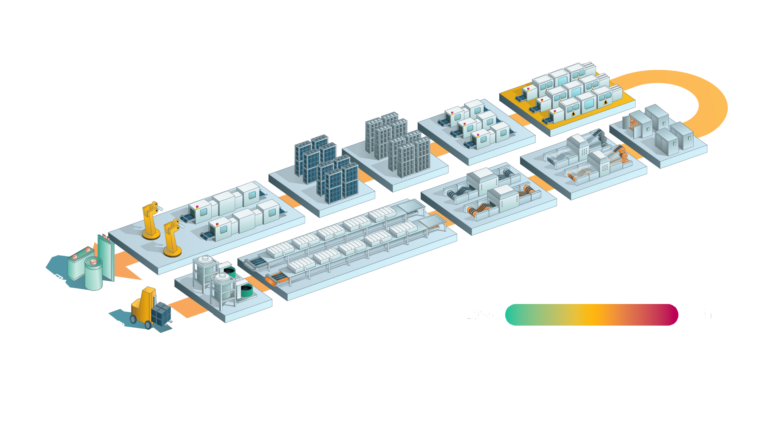

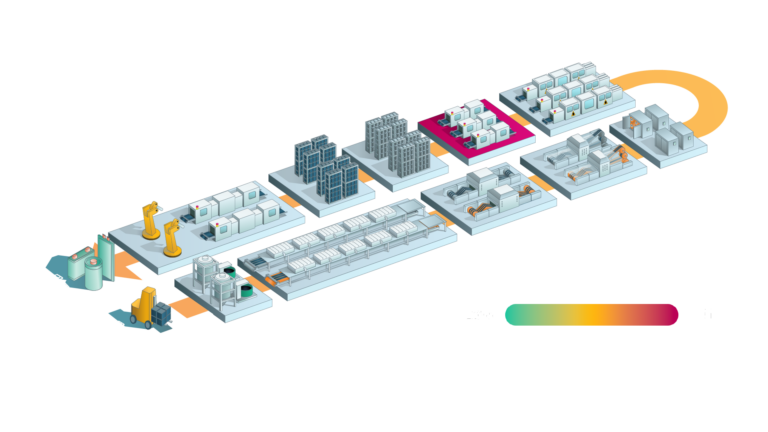

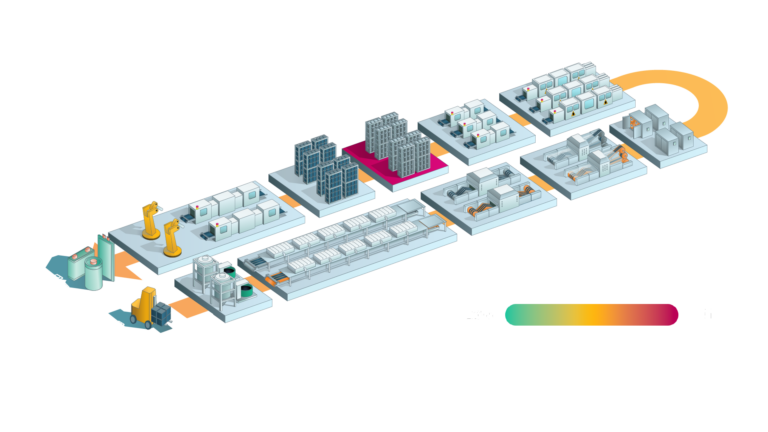

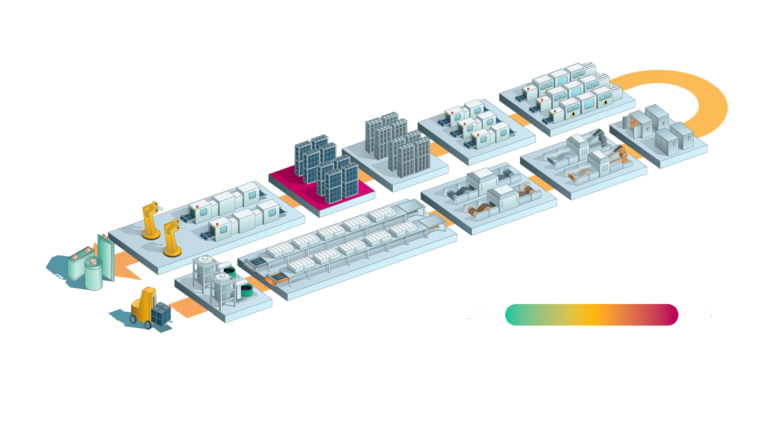

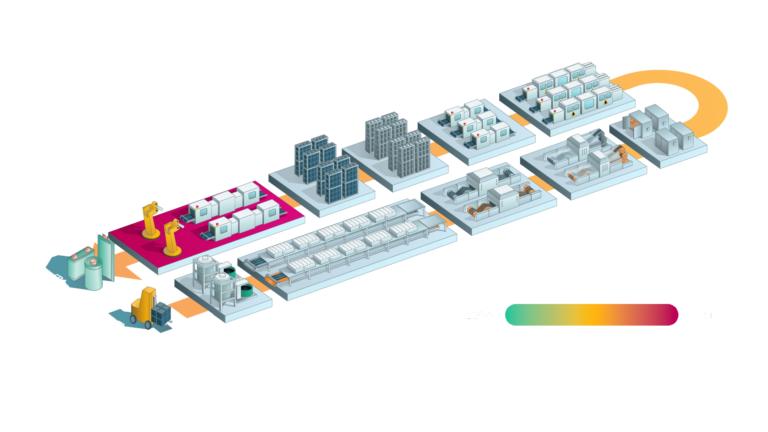

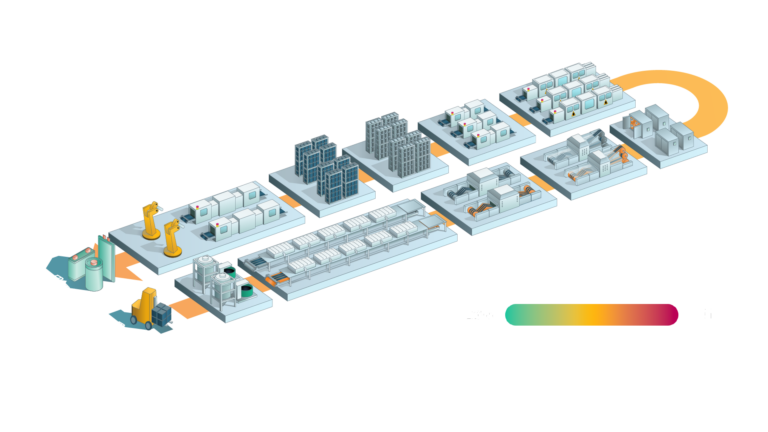

Heatmap of Cost

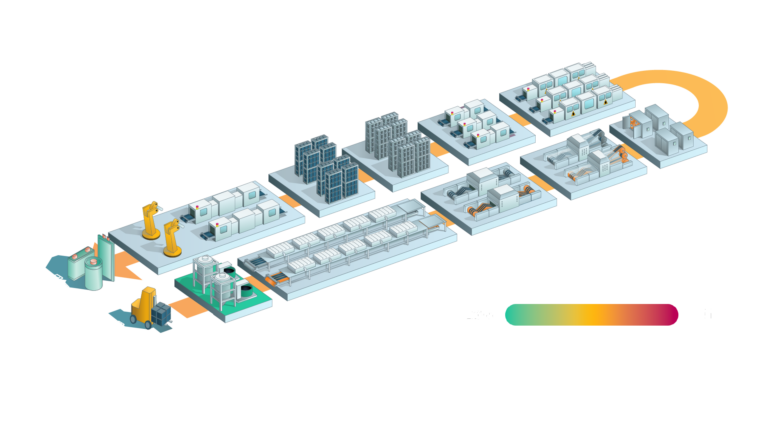

Incoming Quality Control

Influence on efficiency and quality of cell manufacturing

The costs associated with the process step of incoming quality control in battery cell production are important for overall efficiency and production quality. Through inspection and testing of incoming materials and components, manufacturers can detect potential defects or quality issues early, thereby avoiding costly rework or scrap in later production. An effective IQC strategy enables companies to reduce their production costs by reducing failures, improving product quality, and maximizing the overall performance of their battery cells.

Dosing & Mixing

A small impact on production costs

Slurry mixing contributes just a small percentage of the total manufacturing cost of lithium-ion-batteries. The cost drivers are related to the cost and reliability of large-scale mixing. The costs encompass various elements such as raw materials, energy consumption, maintenance, and labor.

One notable cost consideration is the expense related to raw materials, such as lithium, cobalt, nickel, and other essential components required for the slurry formulation. Fluctuations in the prices of these materials impact the overall cost structure of the dosing and mixing stage. Furthermore, the operation of mixing equipment and associated machinery requires a comparatively low amount of energy.

Maintenance is an ongoing cost factor associated with ensuring the proper functioning of dosing and mixing machinery. Regular maintenance schedules and the use of reliable equipment can help to reduce costs in the long term by preventing unexpected breakdowns and interruptions to the production line. In this context, labor costs are incurred in the dosing and mixing phase, which affect the personnel responsible for monitoring the formulation process, equipment monitoring and quality control. [1]

The investment cost for the mixing process ranges from €2.3 million to €4 million per GWh of battery cell production capacity per year.

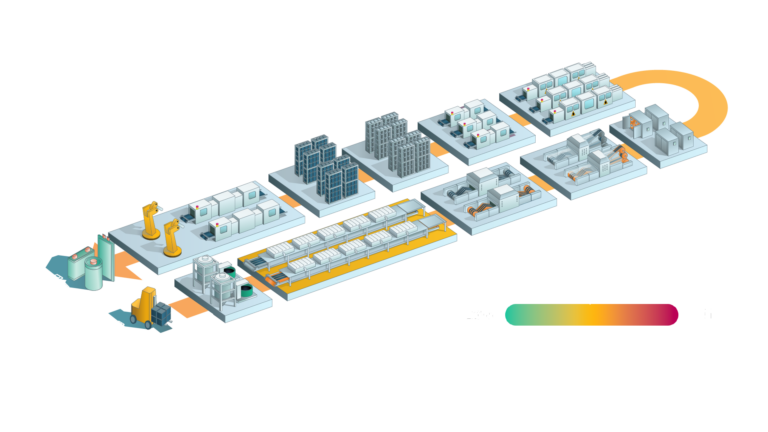

Coating & Drying

Main costs through energy consumption

The coating & drying phase involves the application of electrode materials onto substrates and subsequent drying processes. One significant cost factor pertains to the raw materials involved in the coating process. These materials, which include electrode active materials, conductive additives, binders, and solvents, contribute substantially to the overall cost structure.

Energy consumption is another important factor. The drying process in particular requires a considerable amount of energy. Implementing energy-efficient drying technologies and optimizing drying parameters are two strategies to curtail energy-related costs and enhance the overall efficiency of the production process.

Equipment costs/maintenance constitutes an ongoing cost associated with ensuring the proper functioning of coating and drying machinery. Costs associated with the coating and drying equipment, includes the selection of suitable mixer systems, coater machines, and dryer units for industrial scale production. Regular maintenance practices and the use of reliable equipment are essential for minimizing downtime and mitigating unforeseen disruptions that could adversely affect production costs. As before, labor costs are inherent to the coating and drying phase, involving personnel responsible for overseeing the coating application, monitoring drying processes, and conducting quality control checks. [1,2]

The investment cost for the coating and drying process ranges from €3 million to €11 million per GWh of battery cell production capacity per year.

Calendering

Roll to roll with low costs

Calendering is a step involving the compression of electrode materials to achieve the desired thickness and density, impacting the overall performance of the battery. Mauler et al. (2021) discusses the cost drivers in the calendering manufacturing step, highlighting the impact of roll-to-roll capacities on the cost of battery cell production. The study emphasizes the importance of process parameters, such as roll-to-roll speed and end-of-line scrap rate, in influencing the cost and efficiency of the calendering manufacturing step. One significant cost factor in the calendering process relates to the raw materials involved. These materials include electrode active materials, conductive additives, and binders.

On the other hand, the calendering machinery requires only a small proportion of the overall amount of energy to exert the necessary pressure on the electrode materials. Equipment cost/maintenance constitutes an ongoing cost associated with ensuring the proper functioning of calendering machinery. Costs associated with the calendering equipment are the selection of suitable calendering machines and any installation expenses. In addition, labor costs are inherent as well, e.g. personnel responsible for overseeing the calendering process or monitoring equipments. [2,3]

The investment cost for the calendering process ranges from €0.8 million to €5.8 million per GWh of battery cell production capacity per year.

Slitting

Lower costs with higher speed

Slitting involves the cutting of large rolls of electrode materials into narrower strips, a step essential for the subsequent assembly of battery components. Various process parameters, such as roll-to-roll speed and end-of-line scrap rate, play an important factor in determining the cost and efficiency of the slitting manufacturing step. Higher speeds may lead to increased efficiency and lower costs. The energy consumption nature of slitting machinery contributes little to operational costs.

Furthermore, the machinery used for slitting operations requires regular maintenance to ensure precision and reliability. Unplanned downtime due to equipment failures can result in increased costs and production delays. Implementing proactive maintenance schedules and investing in high-quality, durable slitting equipment are essential strategies for cost containment. In this context, trained specialists are necessary. [2,3]

The investment cost for the slitting process ranges from €0.6 million to €2.3 million per GWh of battery cell production capacity per year.

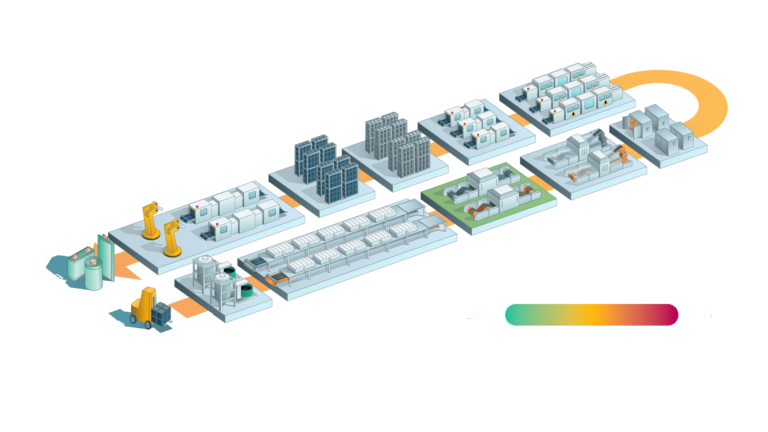

Vacuum Drying

Time as a cost driver

Vacuum drying can be described as removing moisture from electrode materials in a controlled environment to ensure optimal electrochemical performance. The time required for the vacuum drying process can impact the overall production cost. Efficient drying processes with shorter drying times can contribute to cost savings. In addition, the effective machine capacity for the vacuum drying process is a critical factor. Higher capacities can lead to increased efficiency and lower production costs. Vacuum drying is an energy-intensive process, with the vacuum pumps and heating elements consuming a significant amount of energy. Skilled operators are required to monitor and control the vacuum drying process. [2,3]

The investment cost for the vacuum drying process ranges from €0.3 million to €10 million per GWh of battery cell production capacity per year.

Assembly

Multifunctional machinery

Assembly involves the integration of various components, including electrodes, separators, electrolytes, and casing, to create a functional battery unit. The level of automation in the assembly process influences both upfront investment costs and ongoing operational efficiency. Strategic implementation of automation and robotics can enhance production speed, reduce labor costs, and improve overall assembly precision. The cost of materials used in the assembly stage refers to the casing and electrolyte. The assembly of lithium-ion batteries involves various energy-intensive processes, including welding, sealing, and testing. [2,3]

The investment cost for the assembly process ranges from €7 million to €18 million per GWh of battery cell production capacity per year.

Electrolyte Filling

Precision and speed are required to lower costs

In the production of lithium-ion batteries, the electrolyte filling process describes the injection of the electrolyte solution into the battery cell, facilitating the ion transfer essential for electrochemical reactions. The primary cost component in electrolyte filling is the electrolyte solution itself. The selection and procurement of high-quality electrolyte materials, including salts and solvents, contribute to overall costs. Efficient sourcing and strategic procurement strategies are essential to manage these costs effectively. In this context, the efficiency of the electrolyte filling process, including fill accuracy and cycle time, are also important.

Quality control measures during electrolyte filling are crucial for identifying any defects or issues early in the production cycle. Implementing advanced quality control technologies and processes helps minimize the risk of producing faulty batteries, reducing costs associated with rework and warranty claims. Furthermore, the investment costs for electrolyte filling technologies are high. [2,3]

The investment cost for the electrolyte filling process ranges from €2 million to €4.5 million per GWh of battery cell production capacity per year.

Formation

The first commissioning of the cell and the cost impact

The formation includes the initial charging and discharging of the battery cells. This makes the process an energy-intensive stage. Managing and optimizing energy consumption during these cycles is essential for controlling operational costs. High-quality formation equipment is essential for control of charging and discharging cycles. Investment in advanced, reliable formation equipment is important to minimize down-time, ensure consistent quality, and avoid costly defects. Upfront capital expenditure on quality equipment can contribute to longterm cost-effectiveness.[2,3]

The investment cost for the formation process ranges from €6.5 million to €45 million per GWh of battery cell production capacity per year.

Aging

Costs to ensure the operation in a realistic environment

Aging involves subjecting the battery cells to controlled conditions, typically at an elevated temperature, to simulate real world usage conditions and assess longterm performance. Against this background, the aging process includes maintaining batteries at elevated temperatures for an extended period, making it an energy-intensive stage and contributing to overall costs. Furthermore, specialized aging chambers and equipment are essential for maintaining precise temperature and environmental conditions. Investment in high-quality, reliable aging equipment is crucial to ensure consistent and accurate aging results. Skilled operators are required to oversee the aging process, monitor equipment, and conduct periodic checks. [2,3]

The investment cost for the room temperature aging process ranges from €1.5 million to €3 million per GWh of battery cell production capacity per year.

End-of-line Quality Control

Quality control and costs

In the End-of-Line quality control, a comprehensive inspection and testing of finished battery products is carried out to ensure they meet stringent quality standards before entering the market. Investment in advanced testing equipment and technology is essential for accurate and efficient quality assessments. Cutting-edge testing tools can streamline the inspection process, leading to quicker and more reliable results. Identifying defects during End-of-line quality control is essential for preventing faulty batteries from reaching the market. However, the costs associated with defect analysis and potential rework can impact overall expenses. Implementing efficient defect analysis procedures and minimizing rework costs contribute to cost control.

Upgrading and investing in advanced quality control technologies can lead to longterm efficiency gains and cost reductions. Continuous evaluation of technological advancements in testing equipment and defect analysis tools is essential for maintaining competitiveness and optimizing costs. Collaborating closely with suppliers to ensure the consistent quality of incoming components can have a direct impact on End-of-Line quality control costs. Establishing strong supplier relationships, implementing supplier quality assurance programs, and conducting regular audits contribute to minimizing defects and associated costs. [2,3]

The investment cost for the end-of-line testing process ranges from €0.5 million to €1.5 million per GWh of battery cell production capacity per year.

Outgoing Quality Control

Last check on products

The costs associated with the Outgoing Quality Control (OQC) process step in battery cell production play a subordinate yet important role in ensuring product quality and customer satisfaction. Through inspections and testing of finished battery cells, manufacturers can ensure that each product meets the required quality standards before it is delivered to the customer. The implementation of an effective OQC procedure helps minimize scrap and recalls, thereby reducing the overall production costs and strengthening customer confidence in the reliability and performance of the battery cells.

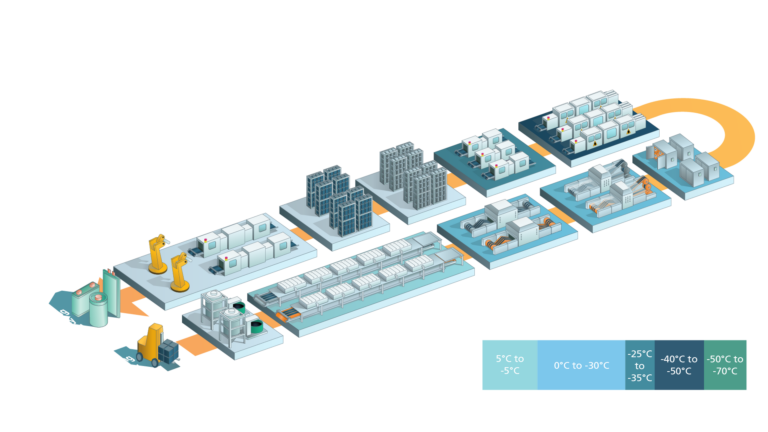

Dryroom

Costs to set up an environmental standard parameter set

Dry rooms, also known as dry chambers or dry boxes, play an important factor in maintaining ultra-low humidity levels to ensure the integrity and performance of lithium-ion-battery components, especially during critical stages such as electrode manufacturing, electrolyte filling, and assembly. Several key factors contribute to the costs associated with implementation and maintenance of dry rooms in lithium-ion battery production:

Investment in infrastructure: The upfront cost of setting up a dry room includes investments in specialized infrastructure, such as airtight chambers, air treatment systems, and humidity control equipment. These systems are designed to create a controlled environment with low humidity levels, usually below 1% relative humidity, to prevent moisture-related issues in battery components.

Humidity control systems: The cost of humidity control systems, including desiccant systems or nitrogen purging, is an essential component. These systems are crucial for maintaining the desired dry conditions within the room. Regular maintenance and calibration of these systems contributes to ongoing operating costs.

Energy consumption: Operating and maintaining a dry room requires a continuous supply of energy, primarily to power humidity control and air treatment systems. Energy-efficient technologies and practices help to minimize ongoing energy costs, making the operation of dry rooms more sustainable and cost-effective.

Temperature control: Besides humidity, temperature control is also important in dry rooms to ensure optimal working conditions for lithium-ion battery manufacturing. The cost of maintaining precise temperature control, especially in large-scale production facilities, adds to the TCO.

Occupancy and footprint: The size of the dry room and the frequency of its use affect costs. Larger dry rooms and those in constant operation may incur higher expenses related to energy consumption, maintenance and the need for additional staff to monitor and control the environment.

Quality assurance and compliance: Dry room setup and maintenance is often driven by quality assurance and regulatory compliance in the battery industry. The costs associated with maintaining industry standards, certifications and routine inspections contribute to the overall in-vestment in dry room facilities.

Technology upgrades: As technology advances, dry rooms may require periodic upgrades to incorporate the latest humidity control and monitoring technologies. Investing in state-of-the-art equipment can enhance efficiency and lead to long-term cost savings.

Downtime and productivity loss: Unexpected downtime due to equipment failure or maintenance can result in productivity losses. Investing in reliable equipment, preventive maintenance and backup systems can help mitigate the impact of unplanned disruptions.

Source:

[1] Liu,Y.; Zhang, R.; Wang, J.; Wang,Y (2021): Current and future lithium-ion battery manufacturing

[2] Oranig, Sina; Hammer Stromann, Anders (2022): A Techno-Economic Model for Benchmarking the production cost of Lithium-Ion Battery cells

[3] Mauler, Lukas; Duffner, Fabian; Leker, Jens (2021): Economies of scale in battery cell manufacturing: The impact of material and process innovations.